Eco-Friendly Packaging

We are committed to sustainable packaging through numerous initiatives with

environmental benefit. This includes simplifying formats, converting 120.4 tons of

conventional box packaging entirely into paper bags in 2023, saving 227 trees.

Our packaging materials achieves forest stewardship certifications like FSC for

responsible forestry and Ecopure for chemical usage guidelines. We exclusively

partner with SGS-accredited suppliers upholding strict, audited measures of social

and ecological impacts.

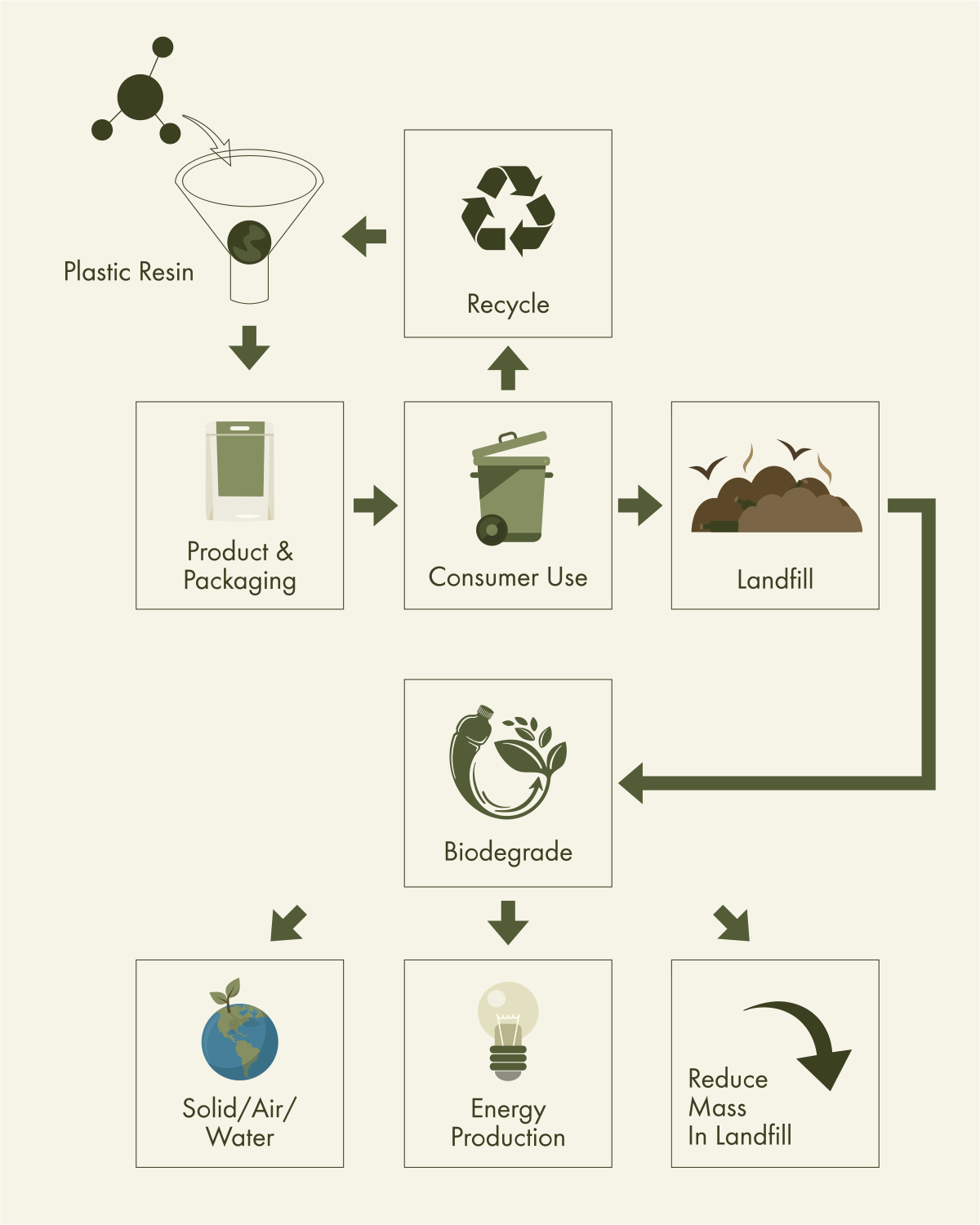

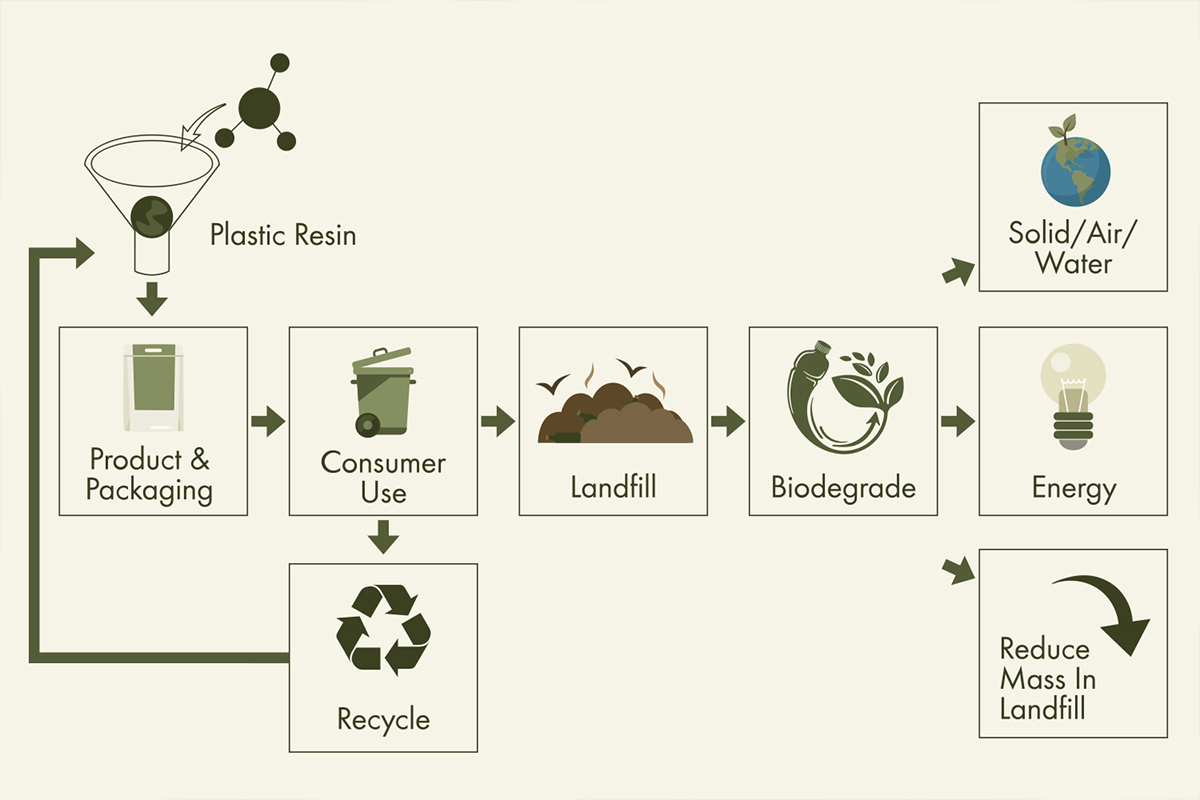

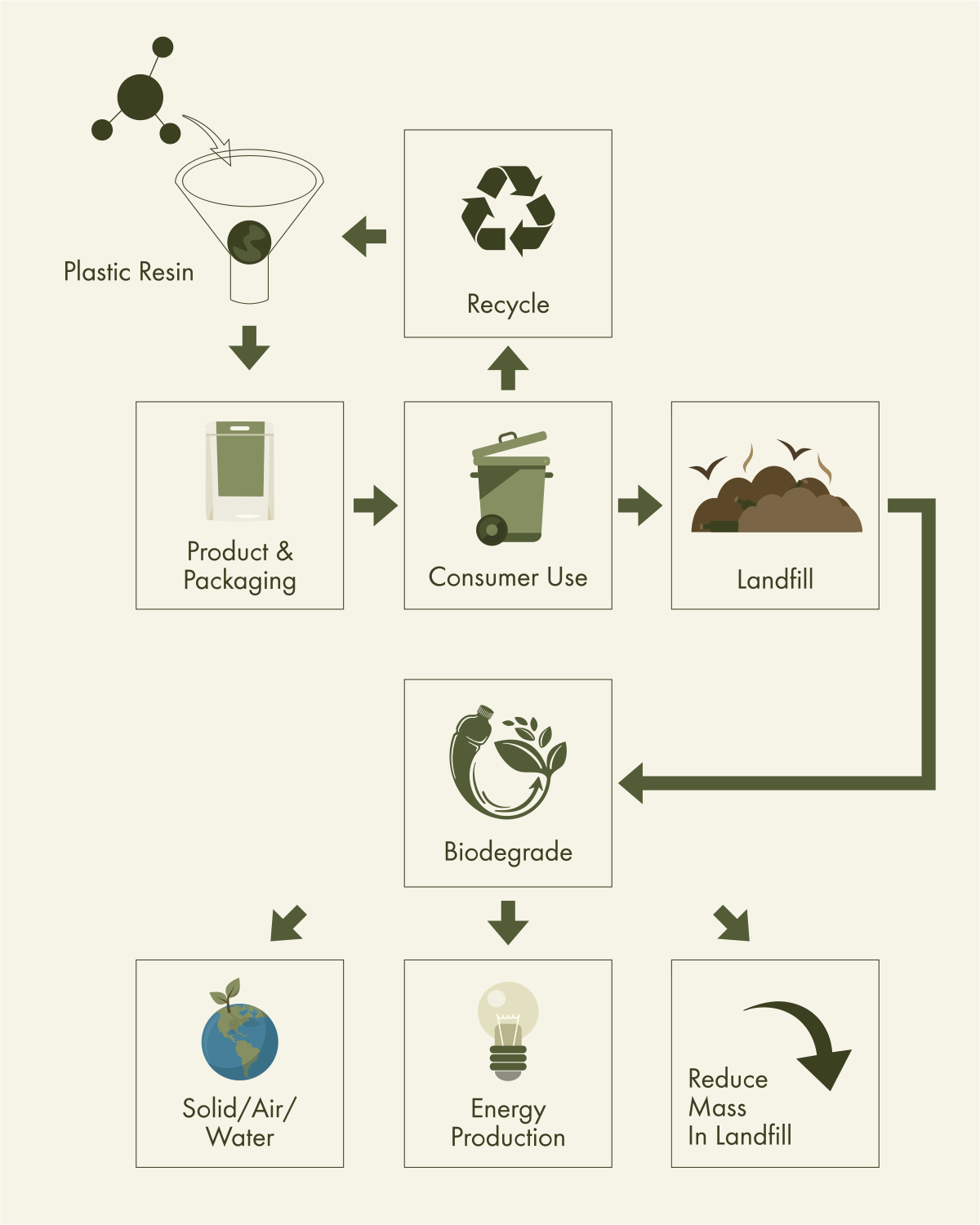

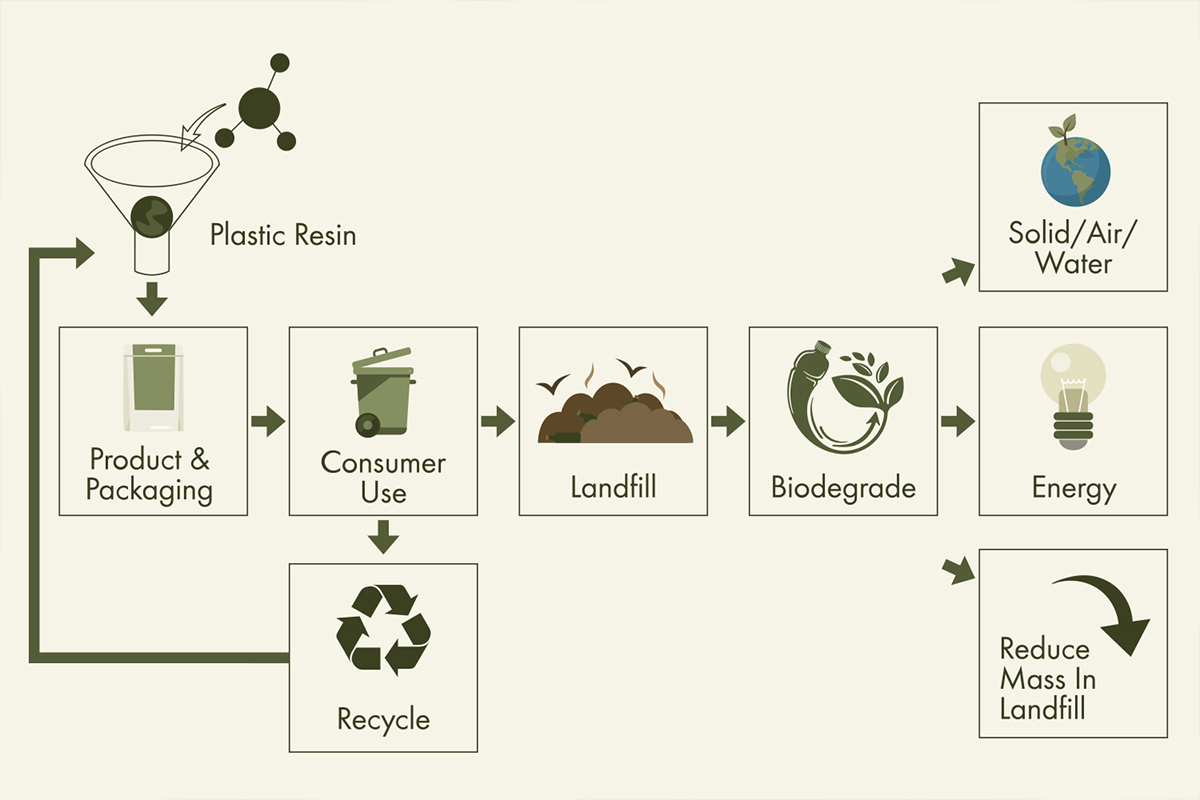

We’ve also increased adoption of biodegradable plastics using organic additive that

accelerates plastic biodegradation process less than 10 years, compared to 500+

years for conventional plastics.